Installation of roof and wall panels for a cold store

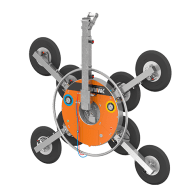

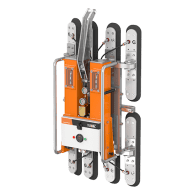

For the installation of sandwich roof and wall panels of the cold store building, different VIAVAC vacuum lifters were used. CladBoy CB4 was used for the roofing, and CladBoy compact for the wall panels. The installation work was done by KIM Nederland, leading specialist in modular insulated construction.

The cold store is composed of a 40 m high steel structure with sandwich panels for the roof. The façade has a thickness of 20 cm and panels up to a length of 19 m.

Strict safety requirements on the construction site

For this project, very strict requirements were set concerning safety on the construction site and the working conditions for the employees. The use of VIAVAC vacuum lifters, among other things, made it possible to install the very long and heavy sandwich panels in a safe and efficient way.

The cold store has more than 21,000 pallet places and a fully automated logistics throughput system at an operating temperature of -17 degrees.

Less about this project